(File C-1) WHAT IS "OPTICAL METHOD OPTICAL BEAM IRRADIATION AND DETECTION MEASUREMENT"?

OUTLINE

Synergy Optosystems proposes optical method optical beam irradiation and detection measurement, and is developing various types of "optical beam irradiation and detection measurement optics" products. In this content, explanation of our "optical beam irradiation and detection measurement", difference between another method, merits and demerits.

WHAT IS "OPTICAL BEAM IRRADIATION AND DETECTION MEASUREMENT"?

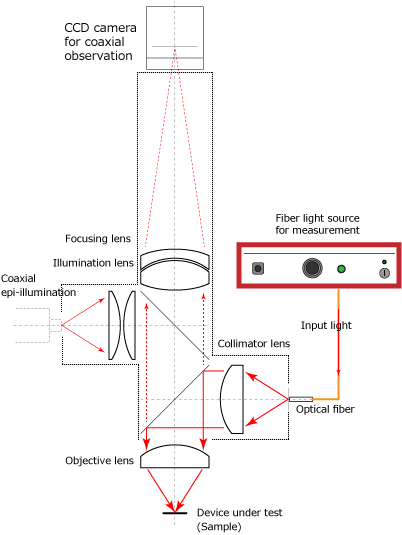

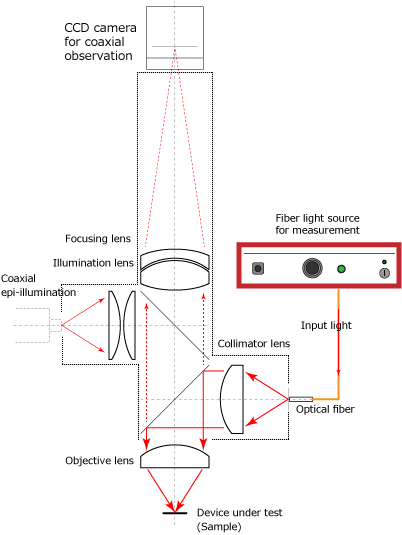

OPTICAL METHOD OPTICAL BEAM IRRADIATION MEASUREMENT

(Fig.1)Structure of optical beam irradiation optics

(Fig.2)Beam irradiation to the photo diode cell

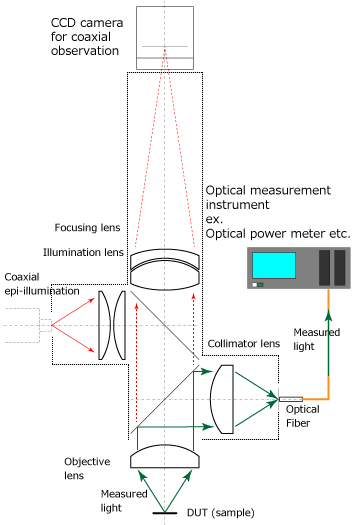

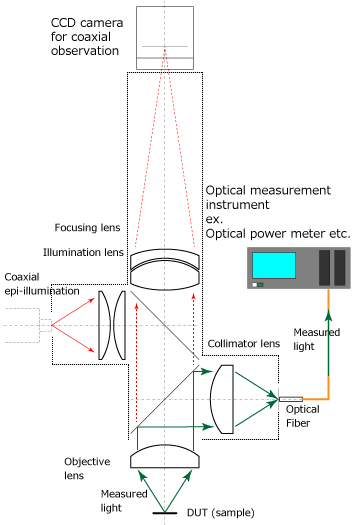

OPTICAL METHOD OPTICAL BEAM DETECTION MEASUREMENT

(Fig.3)Structure of optical beam detection optics